We offer a broad range of services to keep your manufacturing needs on schedule and as specified.

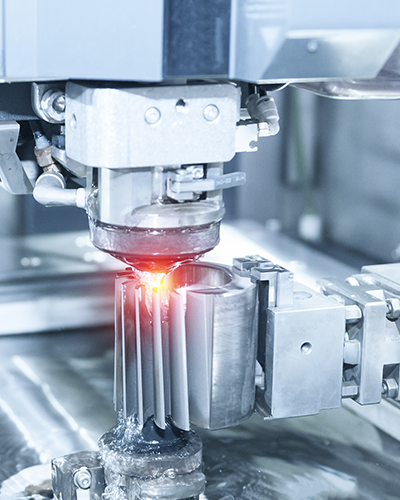

Wire EDM technology has been used in manufacturing since the 1960s, but today’s EDM machines are far more advanced thanks to CNC assistance. They can sense the wire and cutting conditions and adjust the cutting speed for highly precise results, even slowing down for corner work.

We can manufacture even the most intricate parts with perfect accuracy and repeatability, whether you need prototypes, short production runs, or large quantities.

Wire EDM might be the best option for you if your project requires small-radius inside corners, tights slots, or a material that’s difficult to machine such as carbide or tool steel that has already been hardened. We use Mastercam to program complex projects.

With state-of-the-art wire EDM machining equipment and advanced programming we provide Wire EDM specializing in large parts greater than 8 inches.

We have two special large-part 4-axis EDMs, capable of work up to 16” thickness. They have the ability to cut tapers. It can hold a part up to a 41 x 32 x 16″ and can cut 23.6 x 15.7 x 16″ area. It is equipped to use .006″, .010″, and .012″ wire